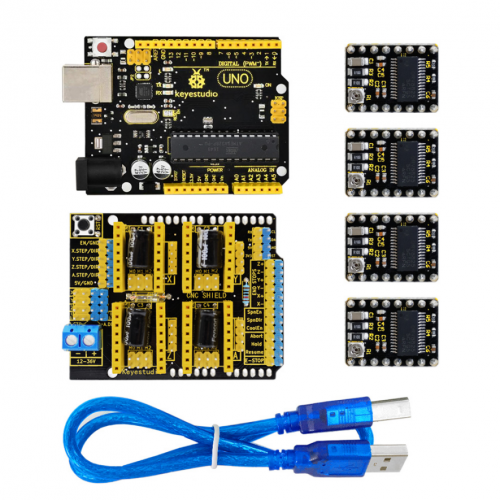

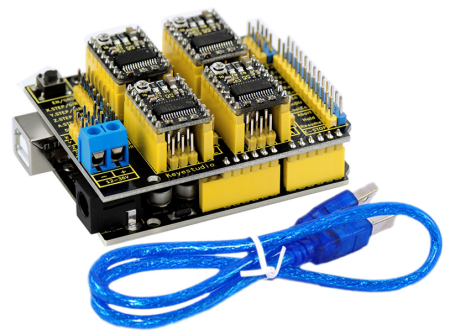

Keyestudio CNC Kit (Shield V3.0 +Uno R3+ 4x DRV8825/GRBL uyumlu)

Contents

Keyestudio CNC Kit / CNC Shield V3.0 +keyestudio Uno R3+4pcs DRV8825 Driver / GRBL Compatible

Tanıtım

Keyestudio CNC Shield V3.0, gravür makineleri için sürücü genişletme kartı olarak kullanılabilir. DRV8825 step motor sürücü modülleri için (dahil değildir) 4 kanal step motor sürmek için toplam 4 kanal yuvası vardır. Her bir step motor kanalı sadece 2 IO portuna ihtiyaç duyar, bu da 6 IO portunun 3 step motoru yönetmek için yeterli olduğu anlamına gelir. Bu kalkan, projenizdeki step motorları yönetmek için hızlı bir iş yapabilir.

Özellikler

- En son Keyestudio CNC Shield Sürüm 3.0

- GRBL 0.8c uyumlu. (G-kodu komutlarını adım sinyallerine dönüştüren bir Arduino UNO üzerinde çalışan açık kaynaklı ürün yazılımı)

- 4 Eksen desteği (X, Y, Z, A-X, Y, Z'yi çoğaltabilir veya D12 ve D13 pinlerini kullanarak özel ürün yazılımı ile tam bir 4. eksen yapabilir)

- Her eksen için 2 x Uç durdurma (toplamda 6)

- İş mili etkinleştirme ve yönlendirme

- Soğutma sıvısı etkinleştirme

- Çıkarılabilir Pololu DRV8825 uyumlu step sürücüleri kullanır. (A4988, DRV8825 ve diğerleri)

- Step sürücüler için Mikro-Adım ayarlamak için jumper. (DRV8825 gibi bazı sürücüler 1/32 mikro kademeye kadar yapabilir)

- Kompakt tasarım.

- Step Motorlar 4 pimli molex konnektörlerle bağlanabilir veya yerinde lehimlenebilir.

- 12-36V DC'de çalışır. (Şu anda sadece Pololu DRV8825 sürücüleri 36V'a kadar işleyebilir, bu nedenle lütfen panoya güç verirken çalışma voltajını göz önünde bulundurun.)

Kit Listesi

- Keyestudio CNC Shield V3.0 *1

- Keyestudio Uno R3 Board *1

- DRV8825 Driver *4

- USB Cable *1

Connection Diagram

Install Driver Software and Development Environment Software IDE

Install Diver Software

- For different operating system, there may be slight difference in installation method. Below is an example in WIN 7.

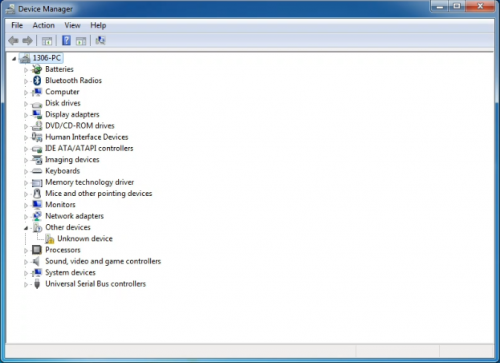

- When you connect Arduino Uno to your computer at the first time, right click "Computer” —>"Properties”—> "Device manager”, you can see "Unknown devices”.

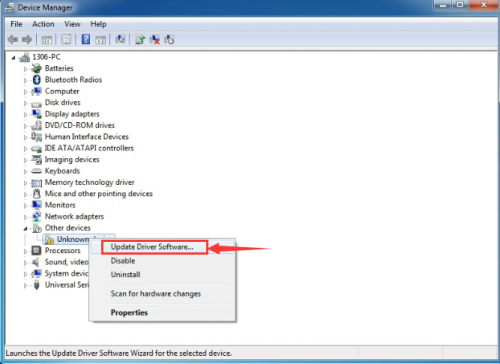

- Click "Unknown devices”, select "Update Driver software”.

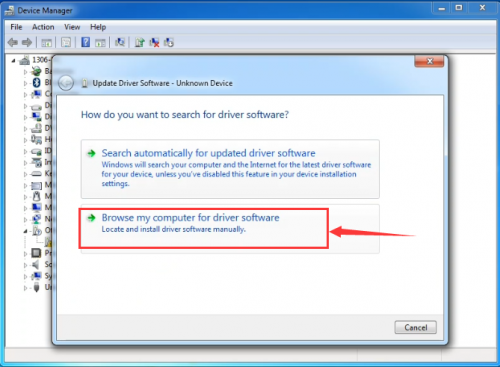

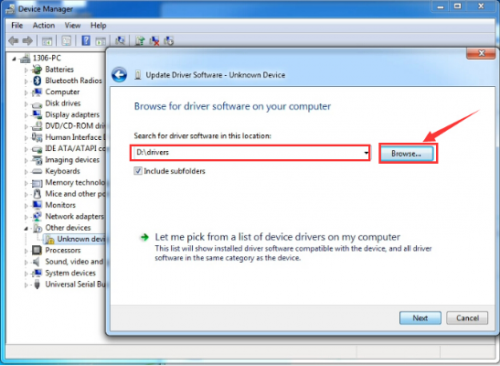

- In this page, click "Browse my computer for driver software”.

- Find the "drivers” file.

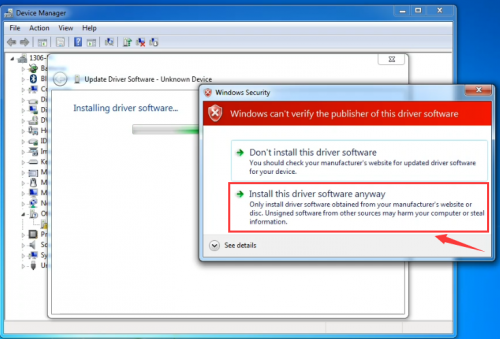

- Click "Next”; select "Install this driver software anyway” to begin the installation.

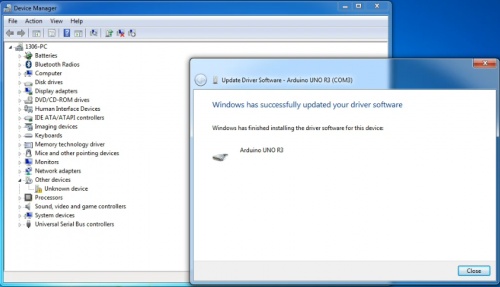

- Installation completed; click "Close”.

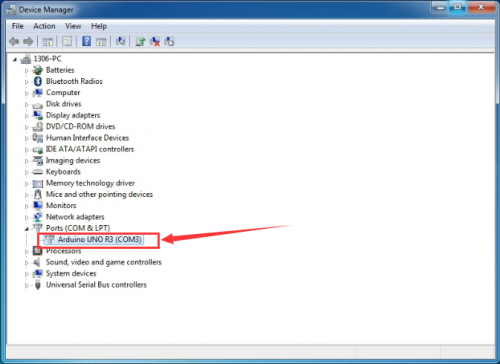

- After driver is installed, go to "Device manager” again. right click "Computer” —> "Properties”—> "Device manager”, you can see UNO device as below figure shown, also the correct Com port.

Install Development Environment Software IDE

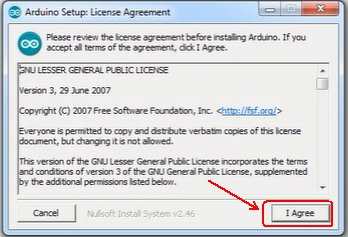

- Double click arduino-1.5.6-r2-windows to start. Select "I Agree”to accept license agreement.

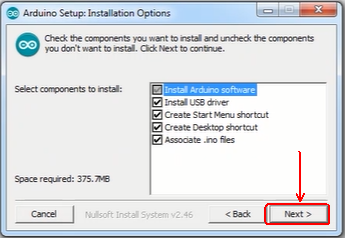

- Select components to install and click "Next”.

- Click "Browse” and select another folder. Click "Install” to start the installation.

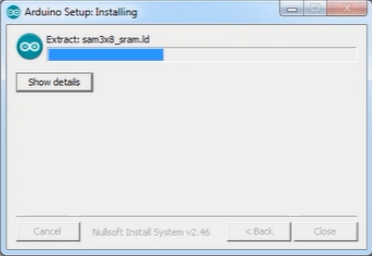

- Finally, wait for a few minutes to finish it.

Using Method

Test Main Board

First, write below code in IDE to test whether main board, shield and three motors work normally.

- Explanation

1. If you properly reduce the value 800 in delayMicroseconds(800) to increase the frequency of input PWM signal, you can increase the rotation speed of stepper motor. The change of value cannot be too much or the motor will stop moving.

2. Rotate the knob on A4988, you can adjust the output current of the motors to change the torque.

- Code as below:

#define EN 8 // stepper motor enable, low level effective

#define X_DIR 5 //X axis, stepper motor direction control

#define Y_DIR 6 //y axis, stepper motor direction control

#define Z_DIR 7 //zaxis, stepper motor direction control

#define X_STP 2 //x axis, stepper motor control

#define Y_STP 3 //y axis, stepper motor control

#define Z_STP 4 //z axis, stepper motor control

/*

// Function: step -control the direction and number of steps of the stepper motor

// Parameter: dir -direction control, dirPin corresponds to DIR pin, stepperPin corresponds to

step pin, steps is the number of steps.

// no return value

*/

void step(boolean dir, byte dirPin, byte stepperPin, int steps)

{

digitalWrite(dirPin, dir);

delay(50);

for (int i = 0; i < steps; i++) {

digitalWrite(stepperPin, HIGH);

delayMicroseconds(800);

digitalWrite(stepperPin, LOW);

delayMicroseconds(800);

}

}

void setup(){// set the IO pins for the stepper motors as output

pinMode(X_DIR, OUTPUT); pinMode(X_STP, OUTPUT);

pinMode(Y_DIR, OUTPUT); pinMode(Y_STP, OUTPUT);

pinMode(Z_DIR, OUTPUT); pinMode(Z_STP, OUTPUT);

pinMode(EN, OUTPUT);

digitalWrite(EN, LOW);

}

void loop(){

step(false, X_DIR, X_STP, 200); // x axis motor rotates CCW for 1 circle, as in 200 steps

step(false, Y_DIR, Y_STP, 200); // y axis motor rotates CCW for 1 circle, as in 200 steps

step(false, Z_DIR, Z_STP, 200); // z axis motor rotates CCW for 1 circle, as in 200 steps

delay(1000);

step(true, X_DIR, X_STP, 200); // X axis motor rotates CW for 1 circle, as in 200 steps

step(true, Y_DIR, Y_STP, 200); // y axis motor rotates CW for 1 circle, as in 200 steps

step(true, Z_DIR, Z_STP, 200); // z axis motor rotates CW for 1 circle, as in 200 steps

delay(1000);

}

Install Firmware and Grbl Controller

a. Write test program to keyestudio UNO R3

- Copy the folder GRBL_ Arduino_Library_keyes in the data packet and paste it into to the folder libraries, in your Arduino IDE document installation.

Code as below:

#includevoid setup(){ startGrbl(); } void loop(){} //Burn the code above to keyestudio UNO R3

b. Install GrblController361 Software

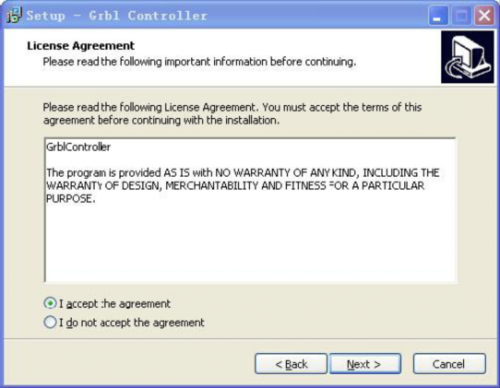

- Grbl Controller is a piece of software which is used to send GCode to CNC Machines. Run Grbl Controller361 Setup in your installation packet, the interface below will come out:

- Click Next to continue.

- For a license agreement, please check I accept the agreement and click Next.

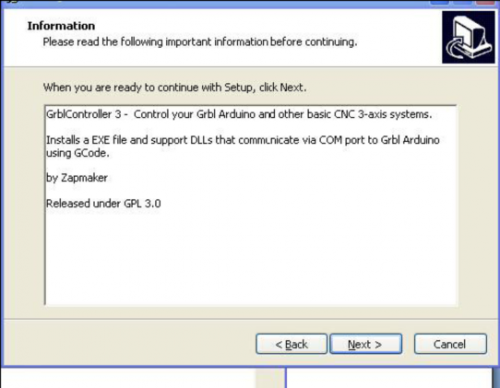

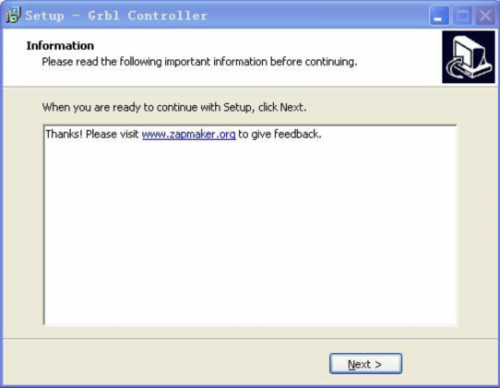

- When you are ready to continue with Setup, click Next.

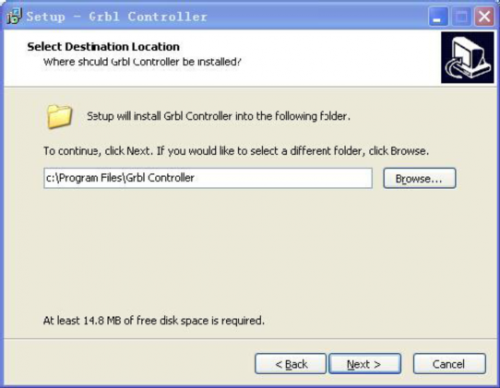

- To continue, click Next. If you would like to select a different folder to install, click Browse.

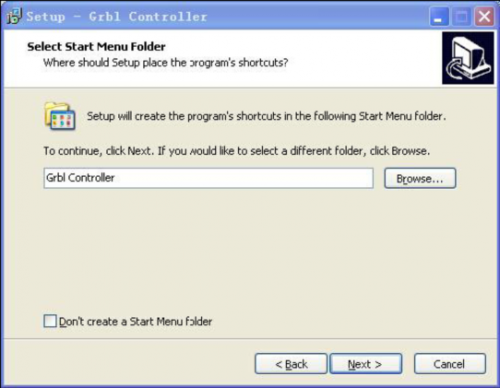

- To continue, click Next. If you would like to select a different folder to place program’s shortcuts, click Browse.

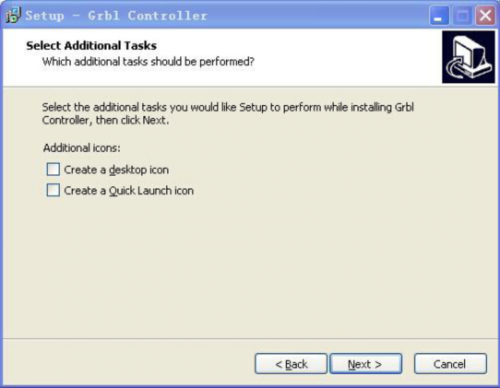

- Select the additional tasks you would like Setup to perform while installing Grbl Controller, then click Next.

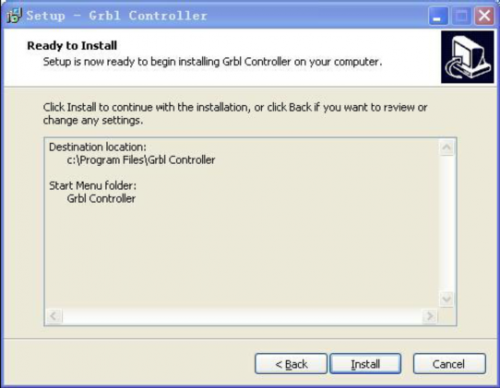

- Click Install to continue with the installation.

- Click Next.

- At last, click ”Finish” to finish the installation.

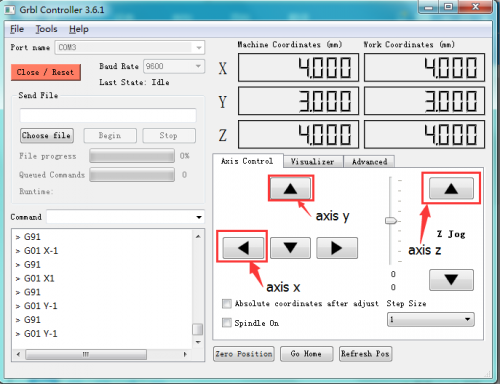

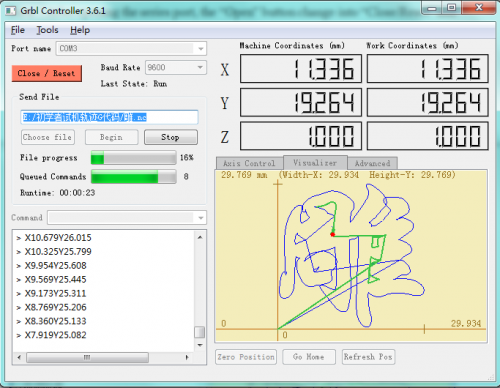

c. Test G-Code on Grbl Controller

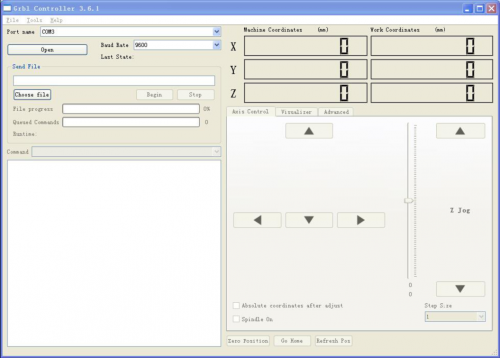

- Power the main board using a USB cable and connect correctly all your external devices, then run Grbl Controller.

- Choose Port name the same as IDE COM port and click "Open” to open the series port, connecting CNC Machines with computer.

- After opening the series port, the "Open” button change into "Close/Reset” and get red!

- At this time you can click the X axis?Y axis?Z axis as shown in below diagram to adjust the motion direction of motors.

- Notes: after adjusting the axies, before beginning G-Code file, you must close and open again .

- Now, it is time to have a try! Click ”Choose file” to choose one G-Code file named cn. to test in the data packet for a beginner, and the interface will come out:

- Click "Begin” , and you can see how the motors move on coordinates.

Reference

Arduino IDE Download:

https://www.arduino.cc/en/Main/Donate

GRBL_Arduino_Library_keyes (Firmware) Download:

https://drive.google.com/open?id=1mmaspMTJAiPvFNpW5ihM-YqeTWKboTKt

Driver Download:

https://drive.google.com/open?id=1IwohNN5tsgm3LzU0kdrBcekGQm--PoPf

G-Code for Testing Download:

https://drive.google.com/open?id=1N5n5n5u4JIh2WLbFyW5VyBaabE2sZb84

Grbl Controller361 Setup Download:

https://drive.google.com/open?id=1Ds6qJSpFfatAwthNaO-6sfFm_xbwCUDS

https://drive.google.com/open?id=1zylbaneVODaTnROmMN-a3XcJJJsLSrG4